Nitrogen is one of the most abundant and versatile gases on Earth, yet its critical role in modern industry is often underestimated. From food and pharmaceuticals to electronics and metal fabrication, nitrogen ensures safety, quality, and efficiency in countless processes. Understanding what nitrogen is, why it’s so valuable, and how it is supplied today is essential for businesses looking to optimize their operations.

Understanding Nitrogen

Nitrogen is a chemical element with the symbol N and atomic number 7. In nature, it exists primarily as a diatomic gas (N₂), making up approximately 78% of the Earth’s atmosphere. Its most notable property is chemical inertness—it does not easily react with other substances under normal conditions. This makes nitrogen ideal for applications where oxidation, contamination, or unwanted chemical reactions must be avoided.

Key characteristics of nitrogen include:

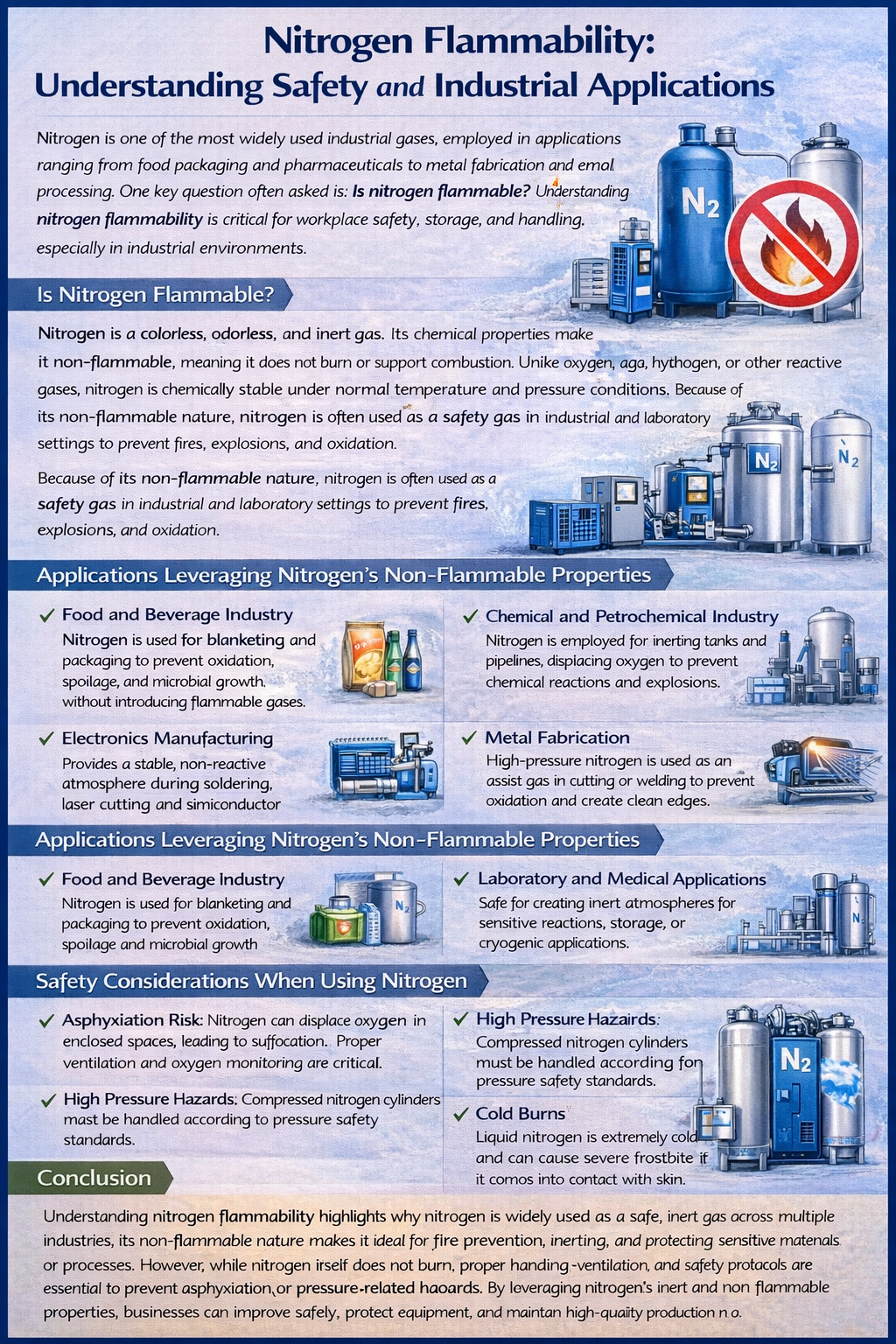

Inertness: Prevents oxidation and chemical reactions in sensitive processes.

Non-toxic and non-flammable: Safe for industrial and medical use.

Cryogenic potential: Can be liquefied at extremely low temperatures for freezing or preservation applications.

Abundance: Readily available in the atmosphere for extraction using modern technologies.

Industrial and Commercial Applications

Nitrogen’s versatility has made it indispensable across multiple industries:

Food & Beverage: Inert packaging with nitrogen prevents oxidation, preserves freshness, and extends shelf life for packaged foods, snacks, and beverages.

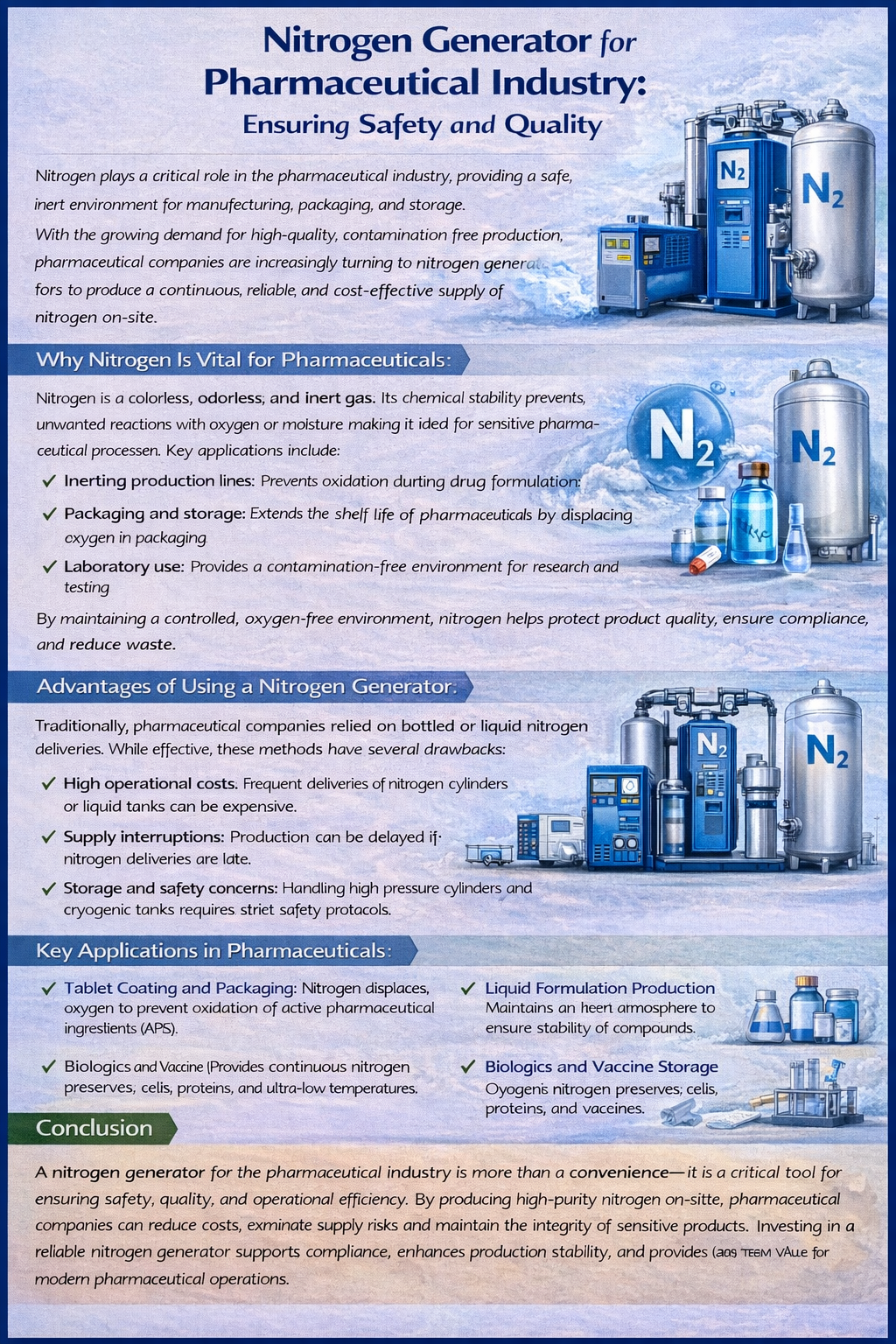

Pharmaceuticals & Medical: Nitrogen provides contamination-free environments, supports cryogenic storage, and is critical in laboratory processes.

Electronics & Semiconductors: Used to create inert atmospheres during soldering, laser cutting, and high-precision manufacturing, preventing oxidation or defects.

Metal Fabrication & Laser Cutting: Nitrogen is employed as an assist gas in cutting stainless steel and aluminum, providing cleaner edges and reducing oxidation.

Chemical & Petrochemical Industries: Nitrogen blankets tanks and pipelines, preventing explosive reactions and degradation of sensitive chemicals.

Challenges with Traditional Nitrogen Supply

Historically, industries relied on bottled or liquid nitrogen deliveries. While effective, these methods have several limitations:

High Operational Costs: Frequent cylinder replacements or deliveries add significant cost.

Supply Inconsistency: Production schedules can be disrupted if nitrogen supply is delayed.

Storage & Safety Risks: High-pressure cylinders and cryogenic tanks require careful handling and space for storage.

Limited Scalability: Adjusting production demands requires additional logistical planning.

Why Nitrogen Generators Are a Game-Changer

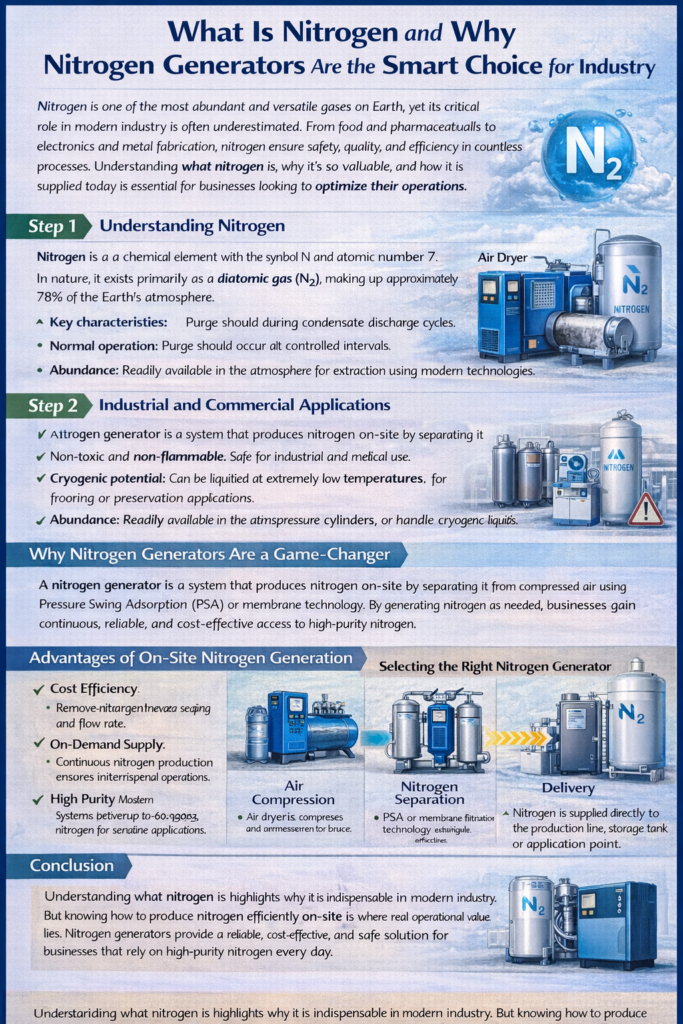

A nitrogen generator is a system that produces nitrogen on-site by separating it from compressed air using Pressure Swing Adsorption (PSA) or membrane technology. By generating nitrogen as needed, businesses gain continuous, reliable, and cost-effective access to high-purity nitrogen.

How It Works:

Air Compression: Ambient air is compressed to feed the nitrogen generator.

Nitrogen Separation: The system separates nitrogen from oxygen and other gases, typically using PSA or membrane filtration.

Delivery: Nitrogen is supplied directly to the production line, storage tank, or application point.

Advantages of On-Site Nitrogen Generation

Cost Efficiency: Eliminates the recurring expense of purchasing bottled or liquid nitrogen.

On-Demand Supply: Continuous nitrogen production ensures uninterrupted operations.

High Purity: Modern systems deliver up to 99.999% nitrogen for sensitive applications.

Safety: Reduces the need to store high-pressure cylinders or handle cryogenic liquids.

Scalability & Flexibility: Generators can be sized to meet small lab needs or large industrial flows.

Sustainability: Reduces logistics-related carbon footprint and overall nitrogen waste.

Selecting the Right Nitrogen Generator

When choosing a nitrogen generator, consider:

Required nitrogen purity and flow rate

Operating pressure for your application

Energy efficiency and compressed air usage

Ease of maintenance and availability of support

Integration with existing production processes

Proper sizing and selection are critical to maximize the return on investment and ensure consistent, high-quality nitrogen supply.

Conclusion

Understanding what nitrogen is highlights why it is indispensable in modern industry. But knowing how to produce nitrogen efficiently on-site is where real operational value lies. Nitrogen generators provide a reliable, cost-effective, and safe solution for businesses that rely on high-purity nitrogen every day. From extending product shelf life to ensuring precise manufacturing processes, investing in a high-quality nitrogen generator delivers measurable benefits in efficiency, safety, and quality control.